Press release -

Safe weighing despite storms and earthquakes

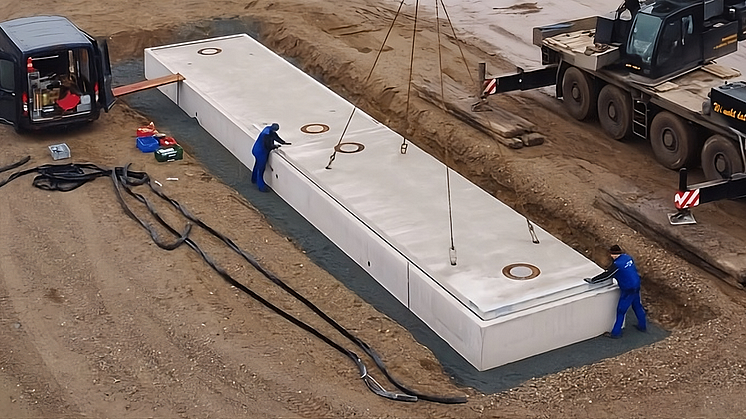

How can a production plant that relies on weighing technology carry out its processes accurately and safely when sudden lateral forces such as gusts of wind, vibrations or seismic activity subject tanks and vessels to great stress? This question arises for many production managers who are confronted with the particular challenges of such environments.

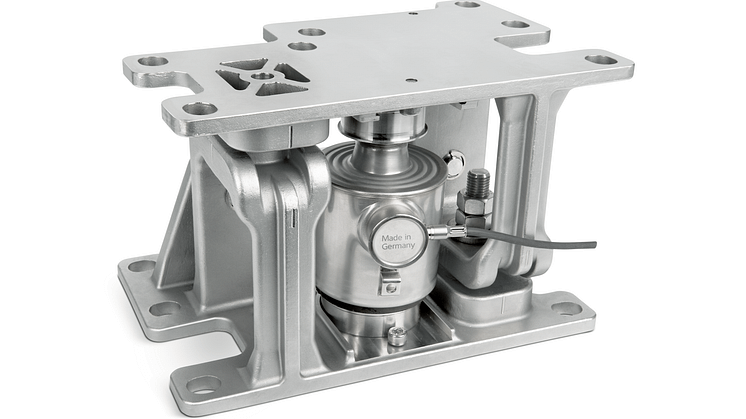

In many regions of the world, managing a production plant is like a constant balancing act: in addition to the everyday challenges of production, production managers have to keep an eye on the risks posed by possible lateral force influences in weighing applications. Storms, vibrations or earthquakes can occur suddenly and expose tanks, silos or other containers to large lateral and transverse forces. Conventional weighing solutions quickly reach their limits here: decreasing measurement accuracy, increasing safety risks and unreliable data impair the entire production process. In addition, constructive approaches often prove to be oversized and expensive. To meet these challenges, Minebea Intec has developed the weighing module Novego® . With its integrated 360° guide arm, it offers a solution that removes concerns of production managers by minimising measurement errors even under extreme lateral and side forces and significantly reducing the risk of damage to weighing components. At the same time, it ensures precise measurements that make production processes safe and efficient - with minimal planning effort thanks to sophisticated adapter options that do not require an external mounting kit.

Maximum precision thanks to innovative technology

The Novego weighing module® is specially designed for use in demanding environments such as earthquake-prone areas. Its innovative design makes it particularly resistant to lateral forces that occur during seismic movements. The module has an integrated self-centring function, which ensures that the load cell automatically returns to its original position after displacement. This ensures that the measuring accuracy is maintained even under extreme conditions.

Moreover, the weighing module is made of high-quality, corrosion-resistant materials that meet the requirements of the Food, Chemical and Pharmaceutical industries. With a maximum capacity of up to 4,400 lb and a protection class of up to IP69, Novego® offers a perfect combination of load capacity and hygiene. The IP69 protection rating ensures that the module is completely resistant to the ingress of dust and water, even during intensive cleaning with high-pressure or steam jets. This makes it ideal for use in demanding production environments where reliability and durability are crucial. The module is also easy to install and can be used without additional mechanical components such as self-aligning bearings or cross-load compensators, which significantly reduces installation costs and time.

With over 70 years of experience in container and silo weighing and a customised range of services - from consultancy assistance and commissioning to maintenance - Minebea Intec supports customers worldwide. This gives production managers peace of mind, even when working under challenging conditions.

Related links

Topics

Categories

Minebea Intec is a leading global manufacturer of industrial weighing technologies. Headquartered in Hamburg, Germany, the company offers products and services that have stood for innovation, performance and reliability for more than 150 years. The product portfolio includes high-resolution platform scales, load cells, hopper and silo scales, as well as intuitive software solutions. Over 1,000 employees at 18 locations increase the precision and efficiency of industrial customers' weighing and production processes. A network of over 200 partners in 71 countries complements the global player's sales and service locations. The high performance and distinctive German quality are reflected in the brand promise "the true measure".

Minebea Intec is part of the MinebeaMitsumi Group, a leading supplier of high-precision production parts such as ball bearings and motors as well as high-quality electronic components such as sensors, antennas and IoT solutions. The Group, which is headquartered in Tokyo and has around 84,000 employees worldwide, reported consolidated net sales of 1,402,127 million yen (approx. 8.9 billion euros) for the 2024 financial year.